Advantages

High cooling capacity for water with low electrical consumption. Cooling of the fluid is achieved using ambient air.

Open-Circuit Cooling Tower

Water is cooled by trickling over a heat exchange body in direct contact with air.

The exchange surfaces and tower casings are carefully selected according to the process to be cooled, water quality, and operating conditions.

- Axial (suction or blowing) ventilation is preferred for its low energy consumption.

- Centrifugal ventilation is used where noise reduction is required.

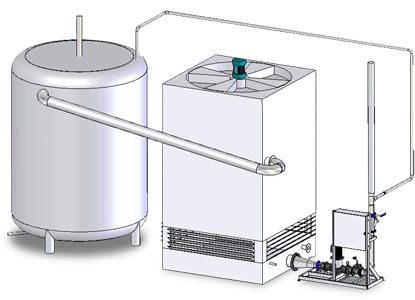

Closed-Circuit Cooling Tower

The fluid to be cooled is not in contact with air. These towers are equipped with intermediate stainless steel plate heat exchangers, fully removable and cleanable, allowing the separation of the evaporative circuit of the cooling tower from the process circuit.

This glycol-free system is protected against freezing; in the event of a power outage, the secondary circuit water drains into the basin, allowing free expansion of the plates.

A self-cleaning centrifugal filter also ensures the removal of suspended solids.

Construction

- Casings and basins are available in galvanized steel, stainless steel, or polyester.

- Exchange bodies (“packings”) are made of polyethylene.

Additional Options

- Motors with variable speed drives for energy savings.

- Sorema can recommend custom water treatment solutions: automatic deconcentration, anti-scale, anti-corrosion, and anti-legionella bactericide.

- Hybrid and adiabatic cooler systems can also be designed.