Applications

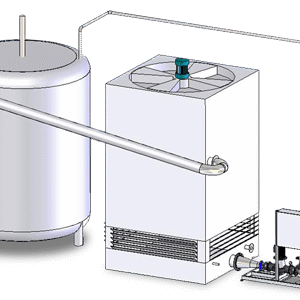

- Cooling of autoclaves, mixers, kettles, and double-jacketed tanks

- Vegetable washing

- Cooling of potable city water for food use

- Cooling of various heat exchangers

Principle

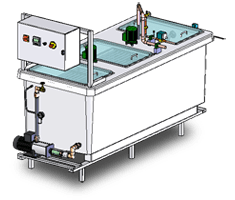

The energy required for process cooling is pre-stored in the form of ice before the temperature drop cycle begins.

- Rapid cooling thanks to the ability of stored ice to absorb a high cooling load at the start of the cycle.

- Flexible operation since ice melts on demand, matching the cooling requirements at different stages of the cycle (high at the start, low at the end).

- Continuous production of +1°C water ensured by forming ice around stainless steel tubes, eliminating the risk of ice buildup inside exchangers—a common cause of total refrigeration unit failure with traditional water coolers.

- Independence from the refrigeration unit, as return water temperature and cooling water flow rate are fully decoupled (accepts high return temperatures).

- Energy optimization: cooling production and storage can be shifted to off-peak hours to lower electricity costs or spread consumption.

- Reduced maintenance costs, approximately half that of conventional water coolers on the market.

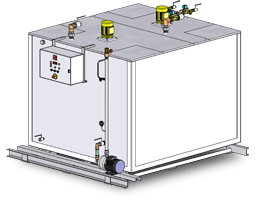

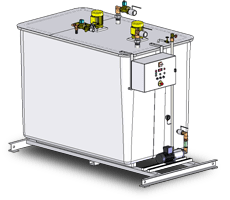

Technical Features

- Polyester tank insulated with polyurethane foam

- 316L stainless steel grid-type heat exchanger

- Exchanger with glycol water at –8°C or with refrigerant gas in direct expansion

- Regulation solenoid valve (glycol-water version) or thermostatic expansion valve (direct expansion version)

- Chilled water distribution pump with safety bypass, flow adjustment valve, and pressure gauge

- Agitators

- Drain valve and overflow protection

- Automatic water refill

- Loop return connection point

- Inspection hatches

- Power and control electrical cabinet

- Refrigeration unit available on request

- Optional frost protection for the pump