Bottom Discharge

- Programmable, but allows for manual intervention

- Can be fitted with Spiralmixer or Wendelmixer

- Able to handle batches of dough from 160kgs to 600kgs

- Automates the entire dough preparation process, from kneading to emptying

Linear Transport System

- Designed to deal with up to 16 batches of dough an hour

- Can deal with a combined amount of 10,000 kgs of dough an hour

- Allows for different dough resting times in the same system

- Can be fitted with Spiralmixer, L-shaped mixer or Wendelmixer

continoMIXX

- Able to knead different types of dough without changing tools

- Machine layout designed to take up little space

- Designed with automatic ingredient dispensing system

- Designed with automatic dough feed

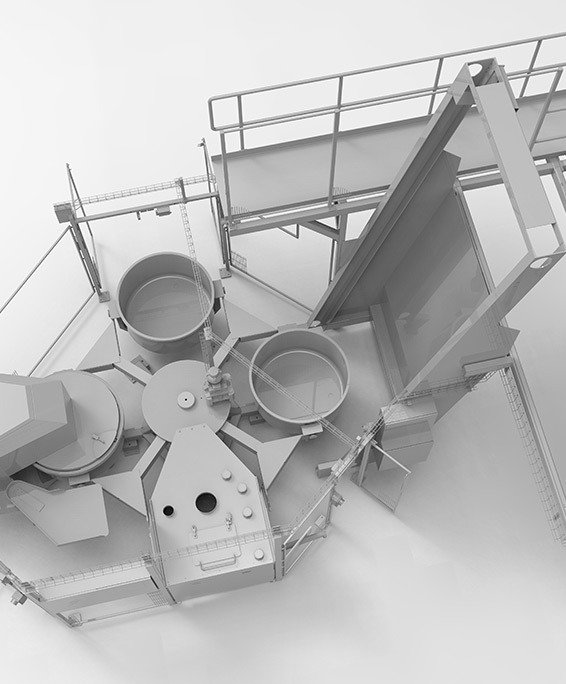

Carousel Principle

- Allows for different dough production processes to occur at once

- Allows for quick recipe changes

- All mixers come with removable bowls

- Allows for smooth operation without disruptions